CNC Ngaktipkeun jenis stainless steel / gandeng fléksibel aluminium pikeun motor

Couplings rahang melengkung

Gandeng rahang melengkung tiasa dianggo dina seueur aplikasi sareng janten gandeng sadaya-tujuan.Desain dasar tina Rahang melengkung ngamungkinkeun pikeun kapasitas torsi luhur dina desain kompak.Waos anu melengkung ngagaduhan daérah kontak anu langkung ageung anu masihan kapasitas torsi anu luhur, sareng ngirangan tekanan ujung.Bakal nampung axial, radial jeung sudut misalignments aci.

The hubs dihasilkeun tina rupa-rupa bahan kaasup: aluminium, kulawu, beusi, waja, baja sintered, sarta stainless steel.Unsur lancah sayogi dina sababaraha pilihan durometer di Urethane & Hytrel.Labah-labah tiasa ngalakukeun dina kaayaan siklus tugas normal dugi ka siklus tugas beurat anu kalebet beban kejut sareng tiasa ngaminimalkeun geter torsional dina sistem.

| Modél | Ukuran bor (mm) | Torsi Dipeunteun (Nm) | Torsi Max (Nm) | Max speed | Diaméter luar (mm) | Panjangna (mm) | Kasabaran Bore (mm) |

| HS -TCN-14C | 3~7 | 0.7 | 1.4 | 45000 | 14 | 22 | +0.6~0 |

| HS-TCN-20C-R | 4~11 | 1.8 | 3.6 | 31000 | 20 | 30 | +0.8~0 |

| HS-TCN-30C-R | 6~16 | 4 | 8 | 21000 | 30 | 35 | +1.0~0 |

| HS-TCN-40C-R | 8~28 | 4.9 | 9.8 | 15000 | 40 | 66 | +1.2~0 |

| HS-TCN-55C-R | 9.5-32 | 17 | 34 | 11000 | 55 | 78 | +1.4~0 |

| HS-TCN-65C-R | 12.7~38.1 | 46 | 92 | 9000 | 65 | 90 | +1.5~0 |

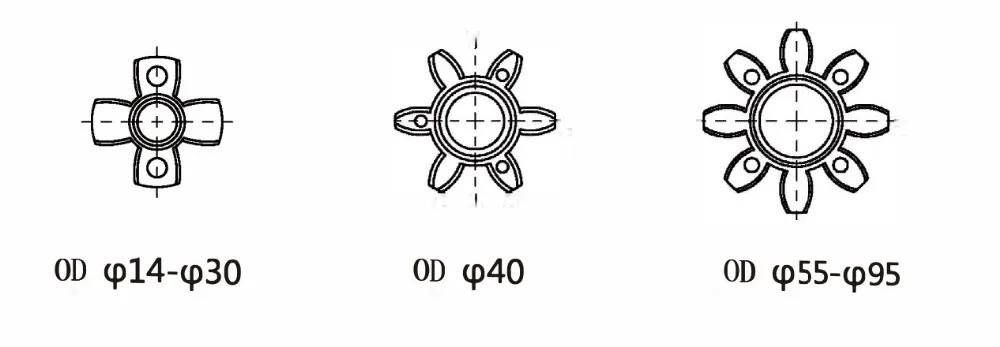

Ciri lancah

Gandeng rahang melengkung ngawengku dua hubs logam jeung hiji elemen "lancah" elastomeric.The spiders sadia di

durometers karasa béda, unggal gampang diidentipikasi ku warna na.

| Teu karasa | Warna | Bahan | Rentang Suhu | Aplikasi |

| 80 Pantai A | Biru | Poliuretana | -50 ~+80 .C | Damping alus teuing |

| 92 Pantai A | Koneng | Poliuretana | -40~+90 .C | damping sedeng, aplikasi umum |

| 98 Basisir A | Beureum | Poliuretana | -30 ~+90 .C | Aplikasi torsi tinggi |

| 64 Pantai D | Héjo | Poliuretana | -50 ~+120 .C | torsi luhur, suhu luhur |

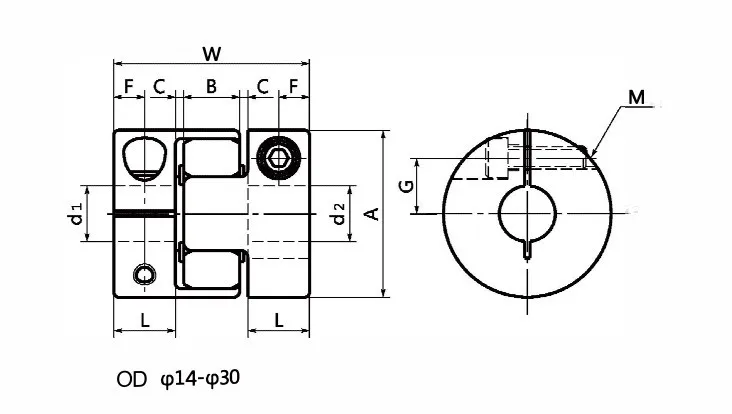

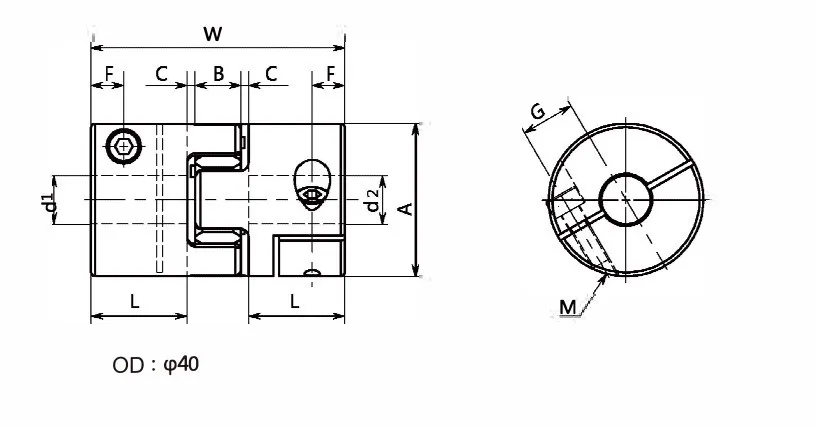

Inpormasi ukuran gandeng

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6,5 / 7,5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |